|

Mark Sennett

Managing Editor |

|

Kelly Rose

Editor |

| Home> | Plant & Machinery | >General Plant & Machinery | >Full service pipe marking |

Full service pipe marking

20 May 2015

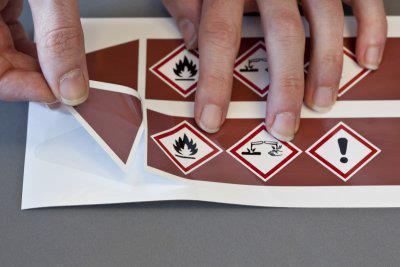

Identification specialist Brady and safety specialist Total Safety together offer full service pipe marking to the chemical, oil & gas, energy, and food and beverage Industries.

"The combination of Total Safety’s worldwide on-site expertise, and Brady’s global identification solutions knowledge, creates a quality partnership able to identify pipes in any plant from A to Z. Together we’ll audit, report, source the pipe markers, implement and coordinate on-site so you can focus on other priorities," says Patrick Block at Total Safety Europe.

Professional and durable pipemarkers not only make a plant visually presentable and compliant with legislation, they are also said to increase the safety and process insight of employees and contractors active in the plant. A simple tap could contain water for example, but might just as well hold pressurised steam, oil, gas or a chemical. Pipe markers immediately inform professionals what to expect, even when they are unfamiliar with a specific plant.

Should a leak occur, well implemented pipe markers with 'to' and 'from' information will quickly show engineers potential leak sources for a quick and adequate reaction. As an added benefit, a clearly identified plant greatly increases the speed at which new employees can be trained.

- Create compliant, safe and efficient workplaces

- New, improved safety sign printers: because safety means the world to you

- Identify pipes in any facility anywhere

- ISO 20560: a global standard to identify pipe contents

- Easily print durable signs

- Effectively combat spills

- Spill control mats

- Safety software showcase

- Sign & label printer

- Control spills, reduce slips