|

Mark Sennett

Managing Editor |

|

Kelly Rose

Editor |

| Home> | Plant & Machinery | >General Plant & Machinery | >Interlock gate switch |

| Home> | Plant & Machinery | >Machine Access Control | >Interlock gate switch |

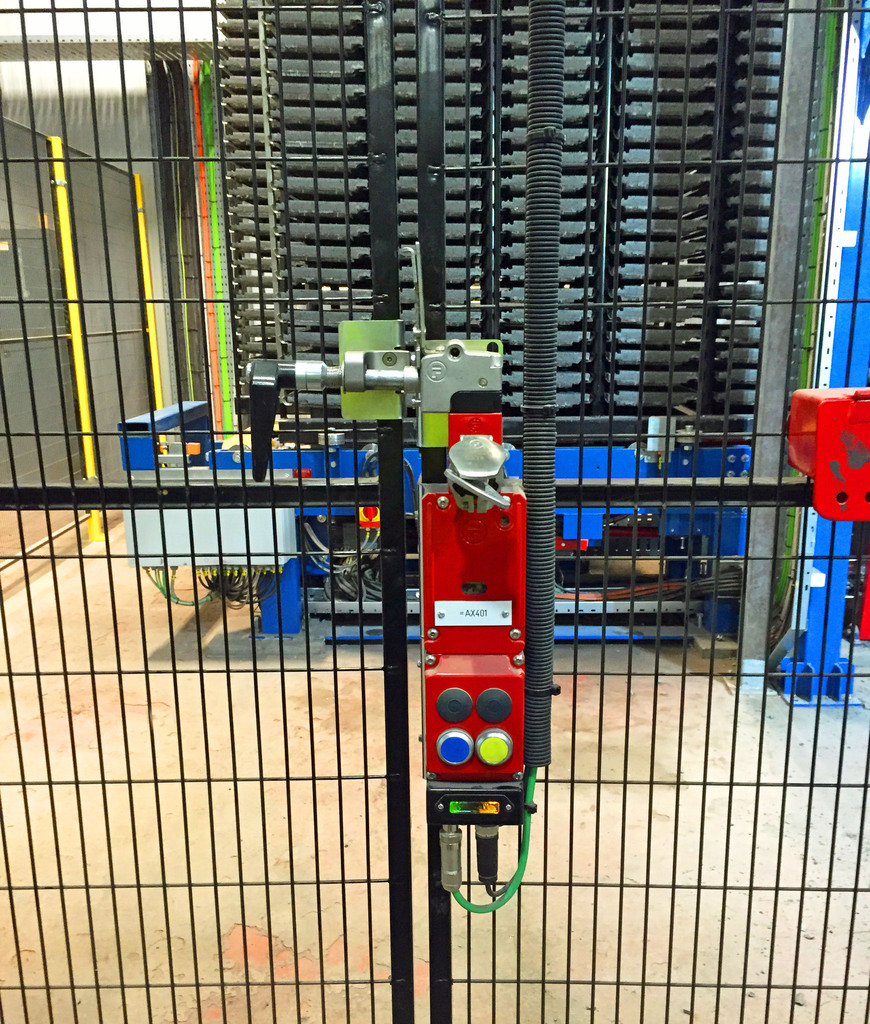

Interlock gate switch

18 July 2017

Brick, block and tile manufacturing plants are notorious for their dusty, arduous environments and high-vibration machinery. This plays havoc with traditional safety interlocks, routinely causing tripping faults.

To overcome this problem, Fortress Interlocks has developed its PROFI-enabled amGardpro interlock gate switch with built-in machine control technology, built to withstand the most strenuous conditions. With a locking force of 10,000N, the PROFI-enabled switch is designed to eliminate virtually all nuisance tripping faults.

PROFINET is claimed to be the world's most advanced industrial Ethernet system for transporting data in real time between control devices (such as PLCs) and field devices (such as safety gate switches).

Using PROFI-enabled amGardpro gate switches allowed a customer of Fortress which manufactures roof tiles to reduce the wiring for each interlock unit, significantly reducing design, engineering, commissioning and maintenance costs and virtually eliminating tripping faults.

The amGardpro is designed to protect personnel from inadvertent machine restart. Every gate switch at the tile manufacturer is fitted with a safety key which must be taken by any worker who enters the guarded machinery. The machinery cannot be restarted until the safety key has been returned to its original position outside the hazardous area. If access for multiple personnel is required, the interlock is fitted with a lock-out clip enabling operators to attach a padlock to the gate switch for Lock-out Tag-out purposes.

Connecting Fortress safety gate switches to a PROFINET network provided an impressive level of diagnostic coverage for the tile manufacturer. Engineers could use standard internet browsers to access diagnostic displays which provided accurate topology views of the network for rapid fault location.

This form of fault detection drastically decreased the level of production downtime, while allowing authorised personnel to access network displays remotely, meaning engineers could diagnose system faults without being on site. The amGardpro PROFINET switches have helped the roof tile manufacturer to make significant improvements in the way the plant is controlled, monitored and managed.