|

Mark Sennett

Managing Editor |

|

Kelly Rose

Editor |

Next level impact protection

05 November 2024

FOR MORE than two decades workers in high hazard industries, have pretty much only had one solution for back of hand impact protection – Thermoplastic Rubber (TPR). You deserve better.

When you’re working in tough conditions, putting your hands in confined spaces and gripping hand tools all day long, you can’t afford for your gloves to hold you back.

"So when we set out to develop a range of impact gloves, we knew we had to look outside of PPE for a technology that could offer end users not just something new, but improved protection and dexterity," says Raymond Rainbird, product manager for Tilsatec.

That’s where KOROYD comes in. KOROYD’s been in the business of impact protection for over a decade, with an impressive legacy of providing impact protection for leading brands of industrial helmets, cycle helmets, motorcycle helmets and body protection – not to mention the US Air Force’s next generation fixed-wing helmet program.

Now they’ve developed their first multiple impact technology for industrial hand protection: KOR+.

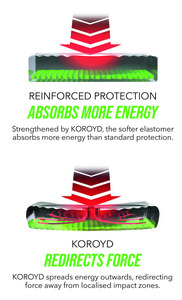

Unlike traditional TPR, KOR+ advanced impact protection technology uses a 2-step damage control system that absorbs and redirects energy away from localised impact zones, limiting dangerous force to reduce the risk of injury.

The unique encased tubular structure allows for multiple impact performance, ensuring it’s always ready to protect when it counts.

Encasing the KOROYD welded tube structure inside a soft elastomer allows it to ABSORB the energy of an impact…

Which it then REDIRECTS away from the impact zone to limit and minimize the impact.

The result of this incredible system is a material which is thin, durable, and lightweight.

At just 6.5mm thick, Collide-x bumpers have a lower profile than the typical ANSI level 2 TPR bumper.

In fact, comparing Collide-x3 6.5mm bumpers to competing 7mm level 2 TPR bumpers, the outcome is an astonishing 38.5% improvement in force reduction.

That’s way above the EN388 impact standard and equal to US ANSI/ISEA 138 impact protection level 3 – with the comfort and dexterity of ANSI level 2.

Imagine a 38% reduction in reportable incidents. Or a 38% reduction in the severity of injuries…

Collide-x combines 20+ years of Tilsatec expertise in cut resistance, yarn engineering and high-performance hand protection solutions with KOROYD’s ground-breaking 2-step damage control technology. Developed with feedback from end users, safety specialists, and market-leading PPE distributors, it took 3 years of research, development, testing and feedback to get it right.

With four styles in the initial range, two seamless coated and two cut and sewn styles all delivering maximum level F cut protection and ANSI/ISEA 138 level 3 impact protection, there is a solution to suit various high hazard industries and applications from oil & gas to mining and construction.

“Much better than current impact gloves on every level… no need to remove them for completing all job tasks, where current gloves make it very hard to use split pins and slotted nuts.”

– Feedback from end user who rated Collide-x excellent for in-use dexterity, feeling, and fit.

“A vast improvement on the gloves we currently use. Dexterity and fit are important improvements and mean that many more tasks are achievable without having to remove gloves from hand.”

– Feedback from end user who rated Collide-x Very good for comfort, dexterity, feeling, fit, wear, and durability.

Now you can demand more and expect better.

Visit the new dedicated website: www.tilsatec.com/collide-x and request the best. Put Collide-x to the test today.

- Tilsatec achieves ISO 17025 accreditation

- Lightweight cut protection

- Cut resistant glove giveaway

- Do your gloves stand up to the test?

- Hand and arm protection testing laboratory

- Tilsatec launches sustainable gloves range

- Protecting hands and arms

- Rhino Yarn Brand Story

- Oil grip glove

- Tilsatec Collide-x impact