|

Mark Sennett

Managing Editor |

|

Kelly Rose

Editor |

| Home> | Trade Body | >BSiF | >Striving for greater competency |

| Home> | PPE | >General PPE | >Striving for greater competency |

Striving for greater competency

06 September 2024

Alan Murray discusses the ongoing need for greater competency in the procurement of Personal Protective Equipment (PPE).

ALTHOUGH THE peak of the pandemic is now four years behind us, the UK continues to face significant challenges with its PPE procurement. Financial disclosures from the Department of Health and Social Care reveal that nearly £10 billion was spent on defective or unusable Personal Protective Equipment (PPE) during the Covid-19 crisis. This troubling figure is further exacerbated by an investigation, by the National Audit Office, which is still struggling to recover millions lost to fraud.

The current government, backed by the appointment of a COVID corruption tsar, has expressed a desire to reclaim some of the funds wasted on unsuitable PPE. However, fundamental issues persist in how PPE is both purchased and distributed across the UK.

The reality is, the longstanding issue of neglecting rules in the procurement of Personal Protective Equipment (PPE) is nothing new. Coupled with insufficient official market oversight in the UK, this has facilitated the entry of substandard and non-compliant products into circulation, endangering unsuspecting users. The British Safety Industry Federation (BSIF) advocates for enhanced proficiency in PPE procurement, aiming not only to elevate safety standards significantly but also to prevent potential future crises.

To the untrained, PPE is a complex and confusing purchase. This is well documented throughout the Covid-19 pandemic with millions consistently awarded to substandard manufacturers. At the height of the pandemic for example, a contract was given to a company which specialises in currency trading and offshore property to deliver fifty million face masks which were found to be unusable, despite being part of a £252m contract. While such figures are staggering, the cost of the potential threat to health and safety from the use of substandard PPE is even more devastating, albeit more difficult to measure.

Under the PPE at work regulations anyone in charge of specifying, buying and providing PPE and safety equipment has a responsibility to select appropriate, approved, certified and compliant products that meet workers' specific requirements.

Due diligence is vital. Buyers and those selecting the PPE must assess the extent to which a product is fit for purpose. They should also look for wearer benefits above and beyond basic protection and make sure it fits comfortably so that it performs correctly. They must also determine whether it is compatible with other PPE that may be required. Yet many people responsible for PPE procurement are not fully aware of their responsibilities or lack the resources to fulfil them.

79% of PPE from non-registered providers failed tests

The volume of substandard and non-compliant products on the market is showing no signs of abating. While the pandemic shone a light on this critical issue, it is still an enormous problem. The BSIF routinely tests a wide range of PPE and safety equipment available across the board, to better understand where these problems lie. In doing so, the BSIF can help to ensure that costly mistakes are avoided, helping to improve the overall standard of PPE and safety equipment available.

The BSIF's latest investigation, spanning from December 2022 to December 2023, paints a concerning picture. Out of the 123 items spot-sourced from non-registered suppliers, a mere 21% passed, leaving a staggering 79% failing to meet even the most basic regulatory and safety criteria. These aren't just statistics; in some cases, lives are at risk.

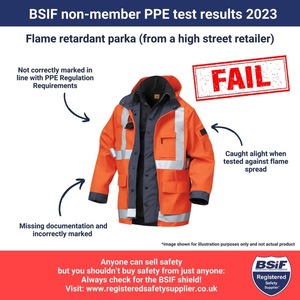

During flame spread testing of a Flame Retardant Parka, for example, which was bought from an online retailer, the outer layer burnt through, exposing the inner layer, which then caught fire, resulting in the entire coat being consumed by flames. The garment also lacked mandatory documentation and markings in line with PPE Regulation requirements.

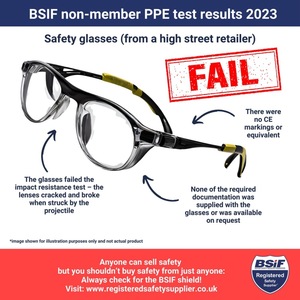

Elsewhere, a pair of safety glasses which were bought from a high street retailer, failed impact resistance testing. No CE markings or equivalent were found to be displayed and the product was missing essential documentation. What’s more, the product was still available to buy over two months later, despite assurances that the glasses would be removed from sale.

The consequences of such negligence extend far beyond financial losses. They manifest in the form of devastating injuries, irreparable harm and broken trust.

The BSIF runs the BSIF Registered Safety Supplier Scheme which provides buyers with assurance that the products they are buying are coming from a compliant, competent and trustworthy supplier. With a remarkable 91% compliance rate during BSIF testing and swift rectification of any shortcomings, these suppliers exemplify high standards in safety and reliability that those specifying and purchasing PPE should demand.

Driving out substandard PPE and safety equipment

To help drive out substandard PPE and safety equipment, sourcing from Registered Safety Suppliers needs to become standard practice. While this is not yet mandatory, the more that people insist on only using these suppliers, the easier it will become to eradicate the issue, helping to prevent a recurrence in the future of what we have seen and experienced in recent times.

The BSIF Registered Safety Supplier Shield can only be displayed by companies whose products and services are subject to tests to ensure they are fit for purpose. This makes procurement far simpler since these audited suppliers are committed to only providing genuine, good quality, products, promising a commitment to authenticity and dedication safety and well-being.

In addition to testing products and services the Registered Safety Supplier Scheme verification process audits that all of the suppliers regulatory obligations and responsibilities have been carried out.

We therefore encourage all those charged with specifying PPE to;

- Check that the supplier is a BSIF Registered Safety Supplier

- Select the correct PPE, using the guidance provided by their qualified staff

- Protect your most valuable asset – your people

Sourcing Safety, a course and qualification

To further support safety and health in the UK market and help specifiers and purchasers of PPE the BSIF are launching “Sourcing Safety” a course and qualification to help educate duty-holders on Personal Protective Equipment (PPE) and assist them in coming to informed decisions when specifying and buying these safety critical items.

To register interest and get more information on “Sourcing Safety” please e-mail [email protected].

Alan Murray is CEO of the British Safety Industry Federation (BSIF). For more information, visit www.bsif.co.uk