|

Mark Sennett

Managing Editor |

|

Kelly Rose

Editor |

| Home> | Industry Update | >Company News | >What's holding your organisation back? |

| Home> | Managing Health & Safety | >Safety Software & Documentation | >What's holding your organisation back? |

What's holding your organisation back?

06 May 2025

THE FIVE biggest safety imbalances holding organisations back — and how to fix them. Scott Gaddis provides an insight.

Introduction: The leadership imperative in safety

The father of modern management, Peter Drucker, once said, “Efficiency is doing things right; effectiveness is doing the right things.” This distinction is particularly relevant in safety management.

Many organisations emphasise compliance—ensuring they are doing things right—but authentic safety leadership ensures they are doing the right things to protect workers, embed safety into business strategy, and drive continuous improvement.

In my book, From Participation to Partnership – A Journey to Safety at the Front Line, I underscore the fact that the most effective safety programs are not built on compliance alone.

Trust, collaboration, and a deep connection with the workforce are equally crucial. The journey from engaging employees in safety to making them true partners in the process is the key to sustaining long-term safety excellence.

However, many companies still grapple with safety imbalances, where one aspect overshadows others. A truly balanced safety strategy integrates multiple dimensions of workplace safety, ensuring no single aspect dominates at the expense of others. This balanced approach is the cornerstone of sustainable workplace safety and a beacon of hope for organisations striving for safety excellence.

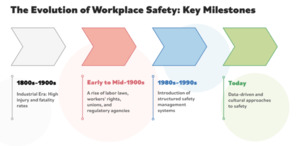

The evolution of workplace safety: How did we get here?

To appreciate the importance of balanced safety strategies, it helps to understand the historical context of safety.

- Industrial Era (1800s–1900s): Safety was non-existent in many industries, with high injury and fatality rates. Regulations were minimal, and employers often prioritised production over worker well-being.

- Early to Mid-1900s: A rise of labor laws sparked by tragic workplace disasters such as the 1911 Triangle Shirtwaist Factory Fire, led to the establishment of workers’ rights, unions, and even regulatory agencies that would follow like OSHA (Occupational Safety and Health Administration).

- 1980s-1990s: Organisations began implementing structured safety management systems such as ISO 45001, integrating safety into operational processes.

- Today: We have seen a shift toward data-driven and cultural approaches to safety. Modern organisations embrace analytics, predictive safety measures, and cultural transformation as key drivers of safety success.

These changes demonstrate why organisations must evolve beyond compliance and adopt a balanced, people-centred, and technology-enabled approach to safety.

The pressures that disrupt safety balance

Despite advancements in workplace safety, business priorities often conflict with safety objectives.

- Efficiency pressure: Forces organisations to meet deadlines and maximise productivity, sometimes at the expense of safety measures.

- Cost pressure: Limits training, equipment, and new technology investment or is directed to production-related activities.

- Innovation pressure: Prioritises speed and production over safety considerations.

- Fatigue pressure: From increased workloads and long shifts leads to decreased focus and higher risks of incidents.

- Conflicting leadership priorities: Including market expansion, talent acquisition, operational priorities, and crisis management, may divert attention and resources away from safety programs.

Much like a tower of Jenga blocks, a well-designed safety management system remains stable until integrity is compromised.

When business pressures force companies to remove critical safety elements, collapse becomes inevitable. The challenge for safety leaders is finding the right balance between these competing pressures while maintaining a strong safety culture.

Implementing a balanced safety strategy is not without its challenges. It requires:

- A shift in mindset

- Significant investment in resources

- A commitment to continuous improvement

However, the benefits, in terms of improved safety performance and business success, far outweigh these challenges.

Five key areas of safety imbalance

An organisation’s most significant challenge is ensuring that its safety programs maintain equilibrium across multiple competing priorities. Many struggle to balance:

- Compliance versus culture

- Incident management versus risk mitigation

- Office administration versus field engagement

- Data collection versus data insight

- Short-term safety actions versus long-term planning

Below, let’s explore these five common areas of imbalance and real-world case studies demonstrating how organisations have successfully

1. Compliance vs. Culture: The Case of Alcoa & Heraeus

Many organisations focus heavily on compliance, ensuring adherence to regulations, policies, and audits. While compliance is necessary, it does not drive engagement or proactive safety behaviours.

Alcoa, under the leadership of Paul O’Neill in the late 1980s, demonstrated how prioritising safety culture could lead to broader business success. O’Neill implemented a policy allowing workers to stop production if they noticed a safety risk. Safety became the first discussion point in all executive meetings, and Alcoa invested heavily in risk mitigation.

As a result, the company’s injury rates dropped by more than 75%, productivity improved, and Alcoa’s market value grew from $3 billion to $27 billion during his leadership period. Paul O’Neill led Alcoa with the value of safety, the marker for which he would assess success.

Similarly, Heraeus, a global technology company, recognised the need to transform its safety culture. In 2019, the company adopted Intelex’s safety management system, which increased process transparency and supported day-to-day operations. As a result, Heraeus reduced Lost-Time Incidents (LTIs) by 10% in Germany and 40% in the United States between 2020 and 2021.

These case studies highlight that organisations must move beyond compliance-driven models and embrace a culture of safety ownership, where workers feel responsible for their safety and that of their peers. Focusing on safety partnerships deep in an organisation leverages better compliance, and both go hand in hand with success.

Read our newest report How to Make Compliance Work for Your Safety Culture (Not Against It!) for more ideas.

2. Managing Incidents vs. Mitigating Risks: The SUEZ Model

Many organisations invest significant resources in investigating incidents but fail to allocate equal attention to preventing them.

SUEZ North America, a water services company, sought to improve safety by implementing an automated system to capture, report, analyse risks, and correct hazards across its facilities. By adopting Intelex’s EHSQ digital solution, SUEZ:

- Increased reporting by ten times, resulting in earlier risk identification and prevention.

- Achieved a 24% decrease in its Days Away, Restricted, or Transferred (DART) rate.

- 41% reduction in its Workers’ Compensation Experience Modification Rate (EMR).

These results underscore the critical importance of proactive risk management.

Instead of waiting for incidents to occur and then reacting, companies must invest in hazard recognition, frontline safety engagement, and leading programming. This proactive approach to safety not only mitigates risks but also promotes a culture of safety and a healthier workplace. It’s a call to action for safety professionals, organisational leaders, and HR managers to be proactive and vigilant in their safety strategies.

3. Office Administration vs. Field Work: The Role of Leadership Presence at George’s Inc.

Safety leaders often become consumed with safety-related paperwork, compliance reports, staff meetings, and other activities, which can lead to a disconnect from the realities of frontline work.

George’s Inc., a major poultry producer, realised that its manual safety processes hindered its ability to identify risks proactively. By implementing Intelex’s EHSQ Platform, George’s Inc.:

- Strengthened its safety culture.

- Improved worker engagement.

- Greatly enhanced connection to the frontline where better communication was warranted.

These changes led to a 54% reduction in the company’s DART rate.

This case study underscores the importance of leadership presence in safety programs. Safety professionals, supervisors, and even senior leaders must spend time in the field, engaging directly with employees to understand their challenges and address hazards in real-time.

4. Collecting Data vs. Using Data: Thales’ Data-Driven Safety Insights

Collecting vast amounts of safety data is meaningless unless translated into actionable insights.

Thales, a global technology leader, needed a digital solution to handle large-scale data collection and analysis. By adopting Intelex’s system, the company processed more than 215,000 safety indicators across its sites, allowing for more precise predictive analytics and better decision-making.

Organisations must ensure that their safety data is not just collected but actively used to drive improvements. Predictive analytics, AI-driven risk detection, and intelligent dashboards can help leaders identify patterns, intervene early, and prevent incidents before they occur.

Thales has been able to use its data differently, allowing it to prescribe better safety process features and make its sites safer.

5. Immediate Actions vs. Long-Term Planning: The Need for Strategic Foresight at Moss

Balancing short-term incident response with long-term strategic planning is crucial for sustaining safety excellence.

Moss, a leader in the construction industry, integrated safety, risk, and claims management into a single platform using Intelex’s software. This approach allowed the company to improve safety reporting, enhance risk assessment, and develop a long-term workforce safety strategy.

Sustainable safety programs require organisations to address immediate hazards while continuously improving their systems and aligning safety goals with broader business objectives.

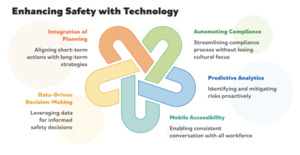

How technology like Intelex helps create sustainable safety balance

Technology has become a crucial enabler of safety balance in modern organisations, ensuring that safety management is effective, efficient, proactive, and deeply embedded in the organisational culture.

Digital safety management solutions, such as those provided by Intelex, help organisations achieve sustainability in their safety programs by addressing the key imbalances discussed earlier.

1. Automating compliance without losing culture

Compliance should not be a paperwork burden—it should enhance safety culture.

Intelex’s software helps organisations automate compliance tracking, regulatory reporting, and proactive activities like safety inspections, audits, and hazard identification to better engage the workforce.

Through customisable dashboards and automated workflows, companies can focus on engagement and safety leadership rather than administrative burdens.

2. Predictive analytics for risk mitigation

Instead of reacting to incidents, Intelex’s AI-driven analytics and predictive risk assessment tools help organisations identify and mitigate risks before they lead to injuries.

By integrating leading indicators such as near-miss reporting, unsafe conditions, and ergonomic assessments, organisations can shift from incident response to actual prevention strategies.

3. Mobile accessibility for field engagement

Field workers often feel disconnected from safety management systems because traditional reporting happens behind a desk.

Intelex’s mobile safety apps allow workers to report hazards, document incidents, and conduct safety inspections directly from their smartphones or tablets, ensuring real-time engagement and immediate corrective actions.

Bi-directional engagement via mobile devices allows for consistent conversation with all workforce members.

4. Data-driven decision-making

Many organisations collect vast amounts of safety data but fail to leverage it effectively.

Intelex enables organisations to centralise, analyse, and visualise data trends, helping leaders make informed decisions about where to invest resources, how to improve safety culture, and which risks to prioritise.

5. Integration of short-term and long-term safety planning

A significant challenge in safety management is balancing immediate hazard control with a long-term strategy.

Intelex allows organisations to track real-time incident data while aligning safety initiatives with business objectives.

With customisable safety performance tracking and automated reporting, leadership teams can monitor progress over time and refine long-term safety strategies based on real-world data.

The future of balanced safety: Data-driven, technology-enabled, and worker-centric

Companies that excel in safety—such as Alcoa, Heraeus, SUEZ, George’s Inc., Thales, and Moss—prioritise a balanced approach.

As workplace safety continues to evolve, integrating technology, cultural engagement, and predictive analytics will define the most successful organisations.

Solutions like Intelex help companies bridge the gap between:

- Compliance and culture

- Reactiveness and prevention

- Administration and frontline work

- Data collection and actionable insights

- Short-term fixes and long-term planning

By leveraging technology to enable balance, organisations can move toward a sustainable, high-performance safety culture where safety is not just a mandated requirement but a strategic advantage that protects people, enhances productivity, and drives business success.

The accurate measure of safety return on investment (ROI) is returning workers home safe and healthy every single day.

With the right leadership commitment, workforce engagement, and strategic application of technology, organisations can achieve a thriving workplace working towards zero harm.

Is your safety program unbalanced?

We developed a quick assessment tool to help you identify gaps between your current and ideal safety program and give you suggestions to bridge the gap.

Scott Gaddis is vice president of Safety and Health at Intelex. For more information, visit www.intelex.com