|

Mark Sennett

Managing Editor |

|

Kelly Rose

Editor |

| Home> | Industry Update | >Company News | >Guide to safety system modernisation |

| Home> | Managing Health & Safety | >Safety Software & Documentation | >Guide to safety system modernisation |

Guide to safety system modernisation

17 June 2025

MODERN EHS teams are under pressure to protect workers, stay compliant, and adapt to growing responsibilities like ESG, sustainability, and total worker health.

But many are still relying on outdated safety systems that weren’t built for the complexity of today’s operations. These legacy tools create blind spots, slow responses, and add administrative burden—when speed and visibility are more critical than ever.

According to independent research and advisory firm Verdantix, 55% of EHS leaders say their goal over the next two years is to implement a single, global EHS software solution, while another 23% are pursuing a unified solution at the regional level. The desire for consolidation reflects a growing recognition that fragmented systems make it harder to collect, track, and act on safety data—especially in diversified, global organisations.

What’s driving the push for consolidation?

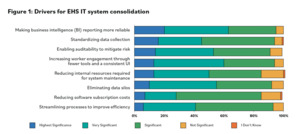

EHS leaders cited the following as the most significant reasons for pursuing system consolidation:

Figure 1

Drivers for EHS IT system consolidation

How significant are the following drivers for EHS IT system consolidation in your firm?

Figure 1. Drivers for EHS IT system consolidation. Based on data from Verdantix, “Global Corporate Survey 2023: EHS Budgets, Priorities, and Tech Preferences,” April 2025.

Key Takeaway: These priorities show that consolidation is about enabling smarter decisions, stronger risk management, and more engaged workers.

This guide will help you:

- Identify blind spots that may exist in your current safety system.

- Understand what a modern safety system should deliver.

- Benchmark your approach against industry trends and technology priorities.

- Recognise the cost of standing still—and the ROI of pulling ahead

For organisations ready to move beyond reactive systems, modernisation offers a clear path to stronger safety outcomes, sharper insights, and a lasting competitive edge.

Section 1. How to Know If Your Safety System has Blind Spots

You might think your system is working fine, but many problems aren’t obvious. Here are key warning signs:

- Field teams are slowed down by outdated tools, with manual forms, limited offline access, and tedious data entry.

- Managers lack real-time visibility. Without live data, you’re reacting to safety issues instead of preventing them.

- Compliance tracking is manual and error-prone, making audits stressful and incomplete.

- Leadership keeps asking for reports. Key decision-makers don’t have access to dashboards with real-time safety metrics.

Checklist: Does Your Safety System Have Blind Spots?

If you answered 'No' to two or more statements, your system is already creating risk and inefficiencies.

|

Indicator |

Yes |

No |

|

Your systems sync seamlessly and eliminate manual data entry. |

||

|

Your team actively uses the system because it’s fast, simple, and intuitive. |

||

|

Compliance tracking is automated and efficient. |

||

|

You have real-time data and predictive insights. Ex. Can you quickly identify and address emerging safety trends before they escalate? |

||

|

Administrative tasks are minimal, allowing teams to focus on safety. |

||

|

Your system integrates with enterprise tools to provide a real-time view of risk. Ex. Can leadership access a complete, real-time view of safety and operational risks? |

||

|

Your platform delivers real-time safety data. |

After identifying potential blind spots in your current system, it helps to see how your priorities compare to those of your industry peers.

Industry Insight: Where EHS Leaders Are Prioritising Technology Investments

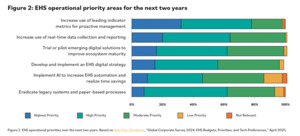

In a 2024 Global EHS Survey, Verdantix gathered responses from 301 senior EHS decision-makers across 24 countries and 25 industries. The findings highlight how executives are adapting to growing responsibilities, such as total worker health, ESG requirements, and complex chemical regulations.

Figure 2

EHS operational priority areas for the next two years

What level of priority are the following EHS operational goals over the next two years?

Figure 2. EHS operational priorities over the next two years. Based on data from Verdantix, “Global Corporate Survey 2024: EHS Budgets, Priorities, and Tech Preferences,” April 2025.

Key Insight: While only 8% of EHS leaders named “eradicating legacy systems” as their top priority, over 90% still rank it as a moderate to high priority. It’s the foundation that enables nearly every other goal on this list—from real-time data collection to proactive safety metrics.

Section 2: What Modern Safety Systems Should Delive

A modern safety system doesn’t just store data—it manages safety risk in the workplace. It should help organisations:

✔Connect safety with operations for better visibility by eliminating data silos.

✔ Make faster, smarter decisions with real-time insights.

✔ Reduce workload and improve accuracy with simplified workflows.

✔ Improve data capture and reporting with mobile tools.

Legacy Vs. Modern Safety Systems

|

Feature |

Legacy Safety System |

Modern Safety System |

|

User Adoption |

Low due to complex interfaces and lack of mobile access. |

High due to intuitive UI, mobile-friendly tools. |

|

Data Access |

Scattered across multiple systems, difficult to retrieve. |

Centralised, real-time access. |

|

Integration |

Siloed, doesn’t sync with enterprise tools. |

Seamlessly integrates with ERP and HR systems for a unified view. |

|

Risk Management |

Reactive. Risks identified after incidents. |

Proactive. Automated reports surface risk identification. |

|

Reporting |

Desktop reporting. |

Desktop and mobile reporting options. |

|

Analytics & Insights |

Limited reporting with static dashboards. |

Advanced analytics and drill-down capabilities. |

|

Scalability |

Hard to scale across multiple sites and regions. |

Cloud-based, grows with business needs. |

|

Reliability & Performance |

Prone to downtime and requires extensive IT maintenance. |

High reliability with cloud-based access and minimal IT burden. |

|

Admin Workload |

High due to manual processes and redundant workflows. |

Automated workflows reduce admin time. |

|

Security & Compliance |

Legacy security protocols increase the risk of breaches. |

Enterprise-grade security with continuous updates and compliance support. |

Section 3: The Cost of Doing Nothing

The industry is shifting to smarter, more connected systems—but many organisations still rely on outdated, disconnected tools. There’s a clear opportunity for forward-thinking companies to gain a competitive edge.

Most companies still use tools that are years behind modern capabilities.

Want a competitive edge? Modernise where others haven’t

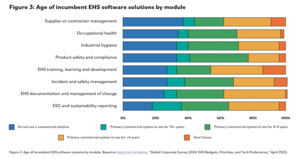

Figure 3

Age of incumbent EHS software solutions by module

When did your firm last implement commercial software for each of the following processes?

Figure 3. Age of incumbent EHS software systems by module. Based on data from Verdantix, “Global Corporate Survey 2024: EHS Budgets, Priorities, and Tech Preferences," April 2025.

What it means: The majority of organisations surveyed are still running on tools that are 4–10+ years old—or have no commercial solution in place at all. These outdated systems create inefficiencies, limit visibility, and make it harder to adapt to new demands. Modernising now gives you a head start. While others play catch-up, you can lead.

The Business Impact of Sticking with Legacy Systems

|

Category |

Key Statistics |

Impact on Business |

|

Regulatory Fines |

OSHA fines up to $16,550 per serious violation and $165,514 per willful or repeated violation.1 |

Financial loss, legal exposure, increased regulatory scrutiny. |

|

Incident Costs |

Average injury costs $40,0002; a fatality costs $1.39M.3 |

Legal liability, reputational damage, decreased morale. |

|

Downtime & Lost Productivity |

Unplanned downtime can cost up to $220K per hour.4 |

Missed production targets, operational delays. |

|

Insurance & Legal Costs |

Employers pay nearly $1B per week in workers' comp.5 |

Escalating insurance premiums, legal settlements. |

|

Technology Debt Costs |

Companies that manage their technical debt experience 20% higher revenue growth than those in the bottom 20th percentile.6 |

Inefficient use of resources, reduced agility and scalability. |

Section 4. The ROI of Modernising Your Safety System

A modern, worker-first safety system reduces incidents, boosts engagement, and improves performance at every level.

While the exact figures will be different case by case, here’s what you stand to gain by upgrading your system.

Stronger Worker Engagement = Fewer Incidents

- Encourages fast, easy hazard reporting (from any device, anywhere).

- Provides real-time feedback to workers on their safety observations.

- Shows employees how their reports lead to real changes.

Data-Driven Safety = Smarter Decisions

- Leading indicators like near misses and hazard reports help predict risk early.

- Automated tracking of safety trends helps identify patterns before incidents occur.

- Real-time dashboards keep leadership informed and ready to act.

Better Data Collection = Stronger Safety Outcomes

- Capture hazards immediately with mobile-first reporting.

- Offline access ensures remote sites can capture data without loss.

- Consistent, structured reporting eliminates inconsistent or missing information.

Here’s how one organisation turned safety system modernisation into a performance advantage:

Customer Spotlight: How Ampcontrol Grew EHSQ Adoption by 14X

Simon Coleman, Ampcontrol General Manager – HSEQ, commented, “Intelex had good local customer service and good local support, and the price was competitive. An important factor was the feedback from other customers that we knew, all of whom had good things to say. We started with Observations because before Intelex, we were doing them on paper, then entering them later on a desktop. We introduced it, people loved it, and we kept building from there.”

Conclusion: Taking the Next Step Toward a Modern Safety System

Outdated EHS systems make it harder to keep people safe, identify risks early, and adapt to changing expectations. They slow down reporting, fragment data, and put pressure on teams to do more with less.

Modernising your safety system removes these barriers. It speeds up reporting, surfaces risks in real time, and gives leaders the insight to act before issues escalate.

Why Intelex is the Ideal Partner for EHS Leaders

Intelex gives organisations the tools to build proactive, connected, and resilient safety programs. With mobile-first technology, real-time risk management, and automated workflows, our flexible platform works the way your teams do—whether in the field, at an operational site, or in a corporate office.

Key Intelex Capabilities for Safer, Smarter Operations

|

Application Builder Tailor safety processes to your unique operational needs with a flexible, no-code platform. |

Document Control Store and manage document versions, approvals, and distribution in one system. |

Mobile & Offline Capability Leverage iOS and Android apps to work without internet and sync data when reconnected. |

|

Reports & Dashboards Gain real-time insights to identify inefficiencies, measure success, and assess risks. |

Connected Data Access and integrate data across multiple applications and systems. |

Form Builder Create, customise, and manage digital forms for data collection. |

Ready to move forward?

✔ Make reporting simple with mobile tools that work in the field—even offline.

✔ See safety risks in real time instead of waiting for reports.

✔ Prevent more incidents by tracking early warning signs.

✔ Spend less time on paperwork and more time improving safety.

Modern safety leadership starts with the right system. Take the next step.

For more information, visit www.intelex.com