|

Mark Sennett

Managing Editor |

|

Kelly Rose

Editor |

In good hands

04 July 2022

In a world increasingly reliant on automation, the hands of workers still play an essential role across a vast multitude of working environments and sectors. John Lambeth explains that health and safety managers need to take a multi-layered approach to provide hand protection solutions that will be embraced by workers.

There are 34 muscles, 27 bones, 48 named nerves and at least 123 ligaments in each hand.

There are also 17,000 touch receptors and free nerve endings found in the palm of human hands designed to pass on vital sensations of pressure, vibration and movement.

Such is their importance that about a quarter of the motor cortex in the human brain is devoted to controlling hand muscles alone.

Yet despite the absolutely vital role they play in our everyday lives, the hands are really quite vulnerable. The bones, nerves, blood vessels and tendons are only protected by a very thin layer of skin, fat and muscle.

Without adequate protection, the hands are exposed to the risks of both minor and severe damage, including cuts, impacts, abrasions, burns, chemicals and temperature changes.

Simply put, the hands are absolutely vital and need to be looked after.

So what are some of the key considerations when it comes to providing workers with the right type of hand safety and protection?

Meeting PPE Regulation and Compliance

When it comes to hand protection, it is vitally important to ensure that the glove you are considering/selecting has been tested and certified against the hazard/hazards you are looking to protect workers from.

To help ensure greater harmonisation and understanding of the levels of protection offered by different gloves, European Union Regulation 2016/425 and it’s UK equivalent PPE Regulation (2016/425) specify the basic requirements, identify hazards, determine the conformity assessment process and act as a framework for using European Standards to assess the level of glove performance according to the type of hazard.

There are three main PPE categories to consider:

-

Category I / Minimal Risk – self certified by the manufacturer

-

Category II – certified by a notified body using a technical file compiled by the manufacturer.

-

Category III – PPE for mortal danger, certified by a notified body using a technical file compiled by the manufacturer and subject to annual inspection (Module C2 or D)

Aligned to this are some of the core European Standards that relate to hand protection including:

-

EN ISO 21420 General Requirements

-

EN374 Chemicals and Micro-organisms

-

EN388 Mechanical Hazards

-

EN407 Thermal

-

EN511 Cold

-

EN60903 High Voltage

Selecting a glove that has been tested and certified to provide the right level of protection against the hazard/hazards being encountered is an essential step in selecting the right protective glove. We strongly advise that if you are unsure of whether the glove/gloves you are considering provide the right levels of protection and are ultimately suitable for the task in hand, you consult a leading hand protection manufacturer to help gain clarification.

But it is not just about meeting UK and EU regulations when it comes to hand protection. There are other criteria to consider - incorporating a glove’s ability to be fit for purpose and meet the workers’ specific needs when carrying out their work.

These considerations include:

Comfort, grip performance

Good hand protection selection is not purely about the levels of protection provided.

There are other critical factors to consider - notably the importance of comfort, grip and performance.

Studies have proven that comfort and grip are both indispensable features that you need to consider alongside the protective performance of a glove.

Importance of Comfort

Comfort contributes significantly to the hand protection process, given that gloves can often be worn for long periods at a time.

Should a glove be too tight, ill-fitting, uncomfortable or irritating for the wearer, there is an increased risk of workers either not wearing the glove or removing it when at work, exposing them to the risk of injury.

There are six key criteria to consider when looking at comfort:

-

Skin contact

-

Dexterity

-

Thickness

-

Elasticity

-

Thermal Properties

-

Perspiration

All these feed into the ‘glove comfort’ selection criteria and should be considered when looking at suitable hand protection solutions for workplace tasks.

From here, you need to consider grip……

Grip criteria

The grip performance provided by a glove is also a key consideration - one that can be all too easily overlooked.

A glove without the correct grip performance can in fact increase the risk of injury through someone dropping what is being handled or through making the task in hand more difficult and inefficient, requiring additional effort, concentration or strain.

This can lead to muscle fatigue, strain or muscular trauma.

The environment in which the glove will be used is critical here and can help determine what grip performance is required.

Will the environment be wet or oily, will the materials handled be greasy or slippery or will the environment change from wet to dry as a result of the task being carried out?

This is where the type of glove material and the type of grip finish become essential.

Different grip finishes provide different performances and include:

-

Raised diamond

-

Roughened

-

Patterned

-

Smooth

-

Foam

-

Double dipped

The factors of grip and comfort can be critical in the hand protection selection process and cannot be overlooked.

What glove material?

The third critical element in the hand protection selection process is the glove material itself.

Different glove materials will offer different types of protection - so it is important to select the right material to protect against the type of hazards (or combination of hazards) the hands are likely to come into contact with,

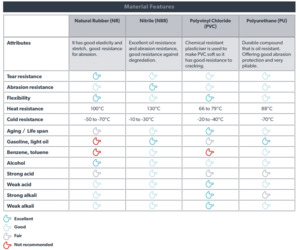

So what are the performance features of some of the major materials used to manufacture gloves?

Key materials include:

Natural Rubber - offers good elasticity and stretch attributes and good resistance against abrasion. It provides the best overall dry grip of any coating especially when it has been processed with a textured latex palm to further enhance grip. It has good durability and strength, and is able to withstand extreme temperatures (environmental). It is important to consider however that latex is not breathable and some users are allergic to latex.

Double Dipped Nitrile - Double-dipping provides extra durability, liquid and abrasion resistance. First dipping a glove into a nitrile coating creates a structured inner layer that repels oil to keep hands dry. It is then finished with a second dip creating another layer that limits the ingress of liquids, keeping the outer surface of the glove in more effective contact with the object being gripped.

Nitrile - Creates a tough coating that provides excellent abrasion and puncture resistance that stands up well to oil, grease and chemicals . Generally finished with an embossed pattern on the palm to aid grip.

PVC - Plasticiser is used to make PVC soft so it has good resistance to cracking in cold conditions

PU - Polyurethane - The lightest, softest, and most flexible of the coating choices. PU is durable and offers the best dexterity and tactile sensitivity— making it a popular choice for comfort and grip. Ideal for dry grip and ease of handling small parts, it’s also good in lighter oil conditions and is also highly breathable offering comfort to the wearer.

The chart below highlights some of the key performance features attributes that each of the main gloves material provide:

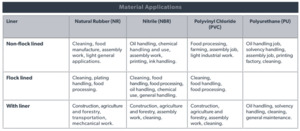

The role and applications of a glove liner

You may wonder what the role of a glove liner is and just how important it is.

For some gloves in industrial settings, glove liners play an important role - enhancing comfort, warmth and protection.

Our guide below highlights the different types of settings where glove materials and linings should be considered.

As we have identified, an effective hand protection programme includes much more than just physical protection.

You need to take a multi-layered approach that takes into account:

-

PPE Regulation, Compliance and Certification

-

Comfort

-

Grip

-

Performance

-

Glove material

-

Glove liner requirements

-

Suitability for the task

Involving workers in the process to ensure that the hand protection you are considering or using is something they are happy and comfortable wearing, enabling them to carry out their work comfortably whilst protecting them against the hand hazards they face, is the ultimate challenge health and safety managers need to meet.

This is ultimately best achieved by working in partnership with hand protection specialists.

John Lambeth is group technical manager at Unigloves. For more information, visit: www.unigloves.co.uk

- Unigloves strengthens its team with hand protection expertise

- Nitrile antimicrobial glove

- Glove sampling service

- Innovative partnership creates Europe’s first antimicrobial nitrile glove

- Unigloves enhances range

- Unigloves extends and enhances range

- Industrial hand protection

- Hand protection for automotive industry

- Give sustainability a hand

- New global identity for Unigloves