|

Mark Sennett

Managing Editor |

|

Kelly Rose

Editor |

| Home> | Handling & Storing | >General Handling | >Loading in a power failure |

Loading in a power failure

11 February 2019

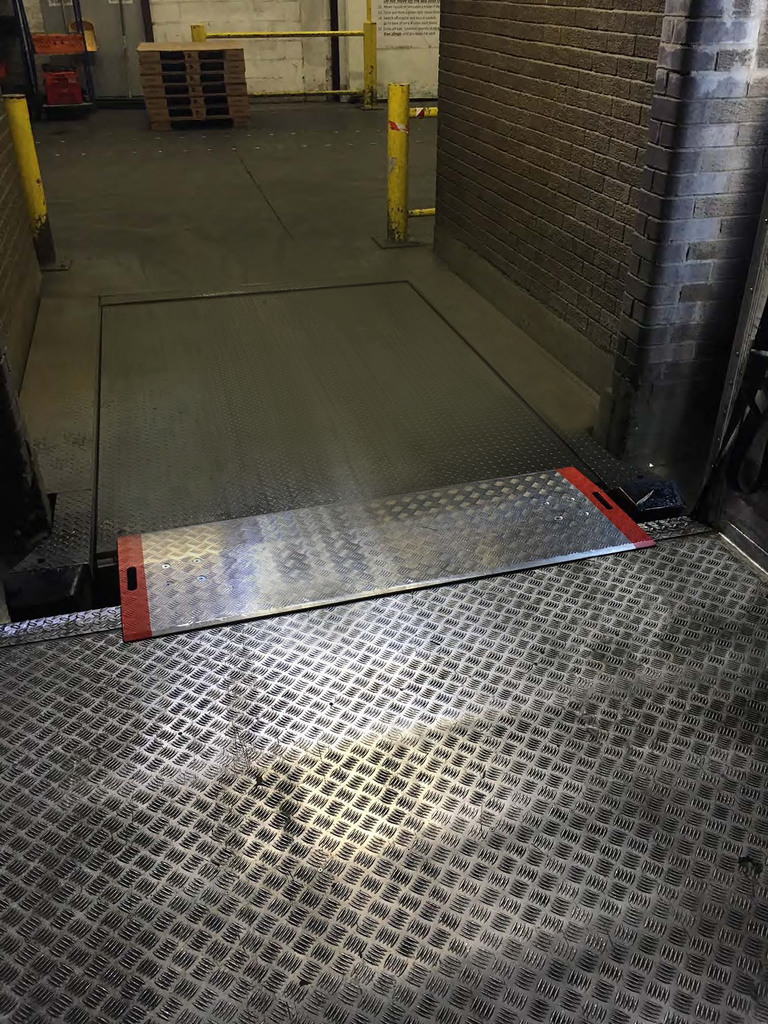

Operating a fleet of 50+ vehicles from a total of 18 loading bays, Long Lane Deliveries already uses four Thorworld hinged bridge plates to provide safe, effective links from dock to vehicle.

“The hinged bridge plates are an ideal solution for connecting the unavoidable gap between our purpose-built van dock and the despatch vehicles,” explains Raymond Nelson Project Manager at Long Lane Deliveries. “However, to enable our operation to continue functioning effectively at all times, we also wanted a further, supporting piece of kit that could quickly be brought into use as a backup to our standard pit mounted dock levellers in the event of a power failure.”

The firm purchased two Thorworld Dock Plates – high tensile aluminium plates, with a built-in anti-slip finish, lifting handles and locking legs designed to prevent movement, for use with pallet trucks, sack trucks and roll cages, and can also enable loading access for pedestrians without the risk of hazard.

- Reel handling solutions

- See the light with LED dock illumination

- Prevents drive-offs

- Major loading bay project

- New innovations

- Savings get the green light from Stertil Stokvis

- Light fitting looks after local sea turtle population

- ATEX loading bays

- Tailored loading bay design

- Support for surveillance