|

Mark Sennett

Managing Editor |

|

Kelly Rose

Editor |

Fabric of safety

23 September 2025

Workers at risk of injury from an electric arc must have suitable protection. Sean Wood provides an insight into the methods for quantifying arc flash risks and guidance on when each method should be used.

Working with electricity carries a risk of being injured by an Electric Arc. It is very important to wear protective clothing covering the whole body to achieve complete protection. To certify Electric Arc garments according to EN 61482-2, the protective clothing must be tested by at least one of the two different test methods: Open Arc EN IEC 61482-1-1 and Box test EN 61482-1-2.

Open Arc - EN IEC 61482-1-1

The test method Open Arc uses an open arc in a medium voltage range (> 1,000V), which is shot towards a fabric sample or a mannequin with protective clothing. Electrodes behind the fabric or garment register the heat transfer through the fabric/garment in order to determine when a person would receive a second degree burn.

In the first stage, the fabric is exposed to different energy levels to obtain an approved Arc Rating. The revised test method is now more strictly controlled and regulated than before, which can mean that previously obtained results may differ from new re-test figures. However, the protection of the clothing is still the same as before, despite the fact that the Arc Rating may sometimes be a lower value after re-testing. In stage two, the protective clothing is tested with the energy level determined by the fabric test result. A new requirement that has been added to the standard in that the tested garment must not have an afterburn time of more than five seconds.

In stage two, the protective clothing is being shot with the energy level from the result of the fabric test. All tests result in two different Arc Ratings based on shooting results and the Stoll curve - which is used to calculate the probability that a person will get a burn. The higher the value, the better the protection.

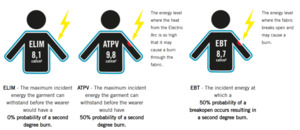

The first result, ELIM (Incident Energy Limit, cal/cm²), lets the user know how much energy the protective clothing can withstand without any risk (or 0% probability) of a second degree burn.

The second result is either ATPV (Arc Thermal Performance Value, cal/cm²) or EBT (Energy Break Open Threshold, cal/cm²), and lets the user how much energy the protective clothing withstands when there is a 50% probability of a second degree burn. ATPV indicates the energy level required when the temperature of the mannequins skin reaches a level where a second degree burn could occur. EBT indicates the energy level at which the fabric breaks open and can result in a second degree burn. ELIM indicates the Arc Rating for the entire garment and as additional information Tranemo also indicates the lowest result of ATPV or EBT.

Since ELIM indicates an energy value at 0% probability of a second degree burn and ATPV/EBT at 50% probability, the ELIM value is usually lower than ATPV/EBT. Large differences between the ELIM and ATPV/EBT results highlight the importance of wearing several layers of garments (such as in a Tranemo Skinsafe system) to ensure you are properly protected.

Box test EN 61482-1-2

The Box test method uses a constrained and direct arc, created by a short circuit in an open cabinet at a low voltage range

(400V). The test is performed on fabric and protective clothing in the same way as for Open Arc. The result is stated as APC (Arc Protection Class):

APC 1 (formerly Class 1) – 168kJ (4kA, 400V), APC 2 (formerly Class 2) – 320kJ (7kA, 400V)

Unlike the American standard, there is not a result scale in this garment tests, only two levels where the garment either passes or

fails. A garment with one layer of Flame Retardant fabric usually passes APC 1 - even thin shirt fabrics.

To pass APC 2, a system with multiple layers or a lined garment is normally required. This makes it more difficult to adapt the protection to the risk, without compromising on comfort.

Quantifying electric arc flash risk for the right protection

One of the most common questions we receive from our customers is about the difficulty of quantifying the risk of an electric arc flash. That is, how strong the arc flash will be if it occurs and how likely it is to happen. In this article, we present two different methods for quantifying arc flash risks and provide guidance on when each method should be used.

Two quantification methods: Calculate or estimate

To solve the issue of quantifying the potential thermal arc energy, several standards and methods have been developed. NFPA 70E is the American standard for Electrical Safety in the Workplace. This comprehensive standard covers many aspects of electrical work, including the use of the IEEE 584:2018 method to calculate thermal arc energy. The method is popularly referred to as an open arc test even though it can be applied in enclosed spaces. In addition, NFPA 70E also includes the method, NFPA 70E 130.7, to estimate the potential arc energy.

DGUV-I 203-077 is the German standard that corresponds to NFPA 70E in Europe and provides support for conducting risk assessments and calculating thermal arc energy. The standard, often referred to as the box test, also includes the BGI/GUV-I 5188 method for calculating this energy.

Below I provide a brief description of each type of method and how they can help you in quantifying arc flash risks. The methods differ because one type is based on calculating the risk while the other provides guidance on assessing and estimating the risk.

Calculate - Incident Energy Analysis within IEEE 1584: 2018 or BGI/GUV-I 5188

The IEEE 1584: 2018 and BGI/GUV-I 5188 methods provide guidelines for calculating the potential thermal arc energy released when an arc is activated. Both methods consider several important parameters, including voltage, short-circuit current, switching time, equipment configuration, working distance and whether the arc occurs in an open or closed area.

By entering the values of these parameters into the equations described in IEEE 1584:2018 and BGI/GUV-I 5188, you can quantify the thermal arc energy and calculate the distance from the arc where the energy equals or exceeds a specified value. This will give you a value of the thermal arc energy that can occur at your expected working distance. This will allow you to find out the distance from the arc where there is a risk of burn injury, also known as the arc flash boundary.

Estimate - Arc Flash PPE Category method within NFPA 70E

NFPA 70E provides you with helpful tools to estimate the potential thermal arc flash energy in an electrical installation. This type of assessment involves comparing your facility against others and making a recommendation on which PPE category of arc flash protection to choose.

It is essential to estimate the incident energy levels that occur in an arc flash, assess the arc flash range and evaluate the probability and severity of potential damage.

Which method is most effective?

The calculation method is more accurate and therefore the most effective method. One of the major advantages of calculating your arc flash risk is that it makes choosing the correct level of protection easier. This results in a more comfortable and cost-effective system of protective clothing.

The assessment method is mainly used when the arc flash risk has not been quantified. For example, when an electrician comes to a site where the risk has not been calculated, he or she can perform a risk assessment according to NFPA 70E and adjust the protection accordingly.

One disadvantage of this method is that it is less accurate than the calculation method. This uncertainty may lead to the user wearing unnecessarily thick and heavy clothing as a precaution.

By following the procedures outlined in NFPA 70E and DGUV-I 203-077, you can calculate and estimate to manage the risk of an arc flash, promoting a safer working environment.

Sean Wood is UK sales director at Tranemo Workwear. For more information, visit www.tranemoworkwear.co.uk