|

Mark Sennett

Managing Editor |

|

Kelly Rose

Editor |

| Home> | Premises | >Safe Access | >Composite demand |

ARTICLE

Composite demand

20 October 2014

International manufacturer Fibrelite has had an increase in enquiries for its lightweight composite access covers from industries keen to move away from traditionally used metal and concrete to composites (a future material).

According to Fibrelite, industries favour composites over traditional materials as they react to changing regulations, strict health and safety policies and concerns with whole life cost.

The design of the Fibrelite covers incorporates up to two lifting points for specially designed lifting handles that allow the operator to remove the cover without trapping fingers or bending over.

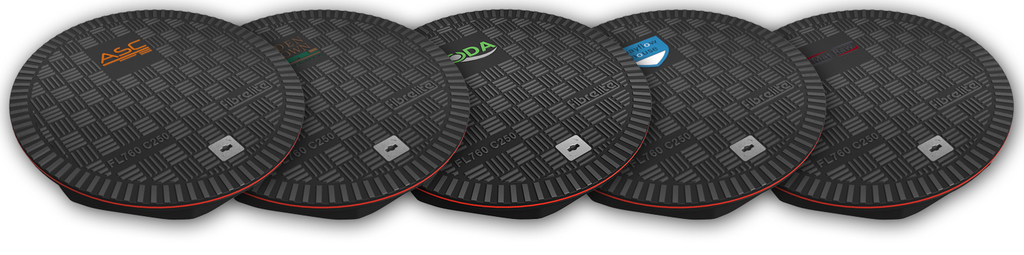

In response to customer demand, any style logo or other marking can be permanently moulded into the upper surface of the cover in single or multiple colours. Fibrelite can mould its composite covers in nearly any colour or combination of colours.

Upon request, Fibrelite can provide bespoke and custom trench covering solutions.

MORE FROM THIS COMPANY

- Concrete and composites partnership

- Manual handling covered

- Fibrelite supplies trench covers for leading cruise terminal

- Bespoke F900 GRP trench covers for UK container port

- Safer access covers

- Fibrelite design and engineer retrofit replacement for heavy cast iron recess access covers

- Composites reach the Antarctic

- Heavy trench covers are history

- Another first from Fibrelite

- New branding and global positioning

RELATED ARTICLES

OTHER ARTICLES IN THIS SECTION