Cutting edge AI technology solutions

STANLEY WILL be on Stand 4/D84 showcasing a range of technology solutions designed to cut accident rates and improve productivity at The Health & Safety Event 2024 at the NEC in Birmingham from 30th April – 2nd May.

Workplace injury is a risk in any business and according to the Health and Safety Executive, every year there are life-threatening workplace accidents involving plant and industrial machinery, as well as hundreds of thousands of back injuries resulting in long term musculoskeletal disorders. Stanley offer a range of data driven technologies that can help reduce these numbers dramatically by identifying risk and helping to improve workplace safety and transform behaviour.

Solutions that will be on show, supplied by Stanley in the UK, include:

- The Sprinter range of powered stair climbers enables suppliers to deliver last mile goods safely and efficiently where access is difficult or stairs are an obstacle. The powered stair climber is light and powerful, meaning that the need for two employees to carry heavy products is reduced and the prospect of injury is also reduced.

- The Inteliforz motion series hand pod which identifies risky hand and wrist movements with a small wearable device that is inserted into a hand wrap, worn over a protective glove. It can capture up to 60 hand and wrist motions every minute to assess risk, allowing workers to view their movements and undertake training and coaching opportunities if needed.

- The Modjoul SmartBelt: an innovative device worn on a belt that uses Artificial Intelligence (AI) technology to prevent injury through real-time feedback and data analysis. The device is designed to measure a range of workplace risks including musculoskeletal risk, repetitive motion, temperature control, PPE compliance, forklift and plant collision avoidance and lone worker safety. Workplace managers and workers have access to a stream of real time data which measures and corrects the way that workers bend, lift, twist, and stretch. The data can be analysed to help provide more targeted health and safety training, identify risk or a change of process.

- Forklift collision avoidance: Modjoul’s Halo 360 collision avoidance system, communicates with forklift drivers and other workers operating in the vicinity. If a forklift is nearby, the technology will alert both the driver of the forklift and the individual concerned so that they can avoid each other. This is useful in areas where vision may be restricted such as blind corners, or when cranes are operating overhead lowering materials.

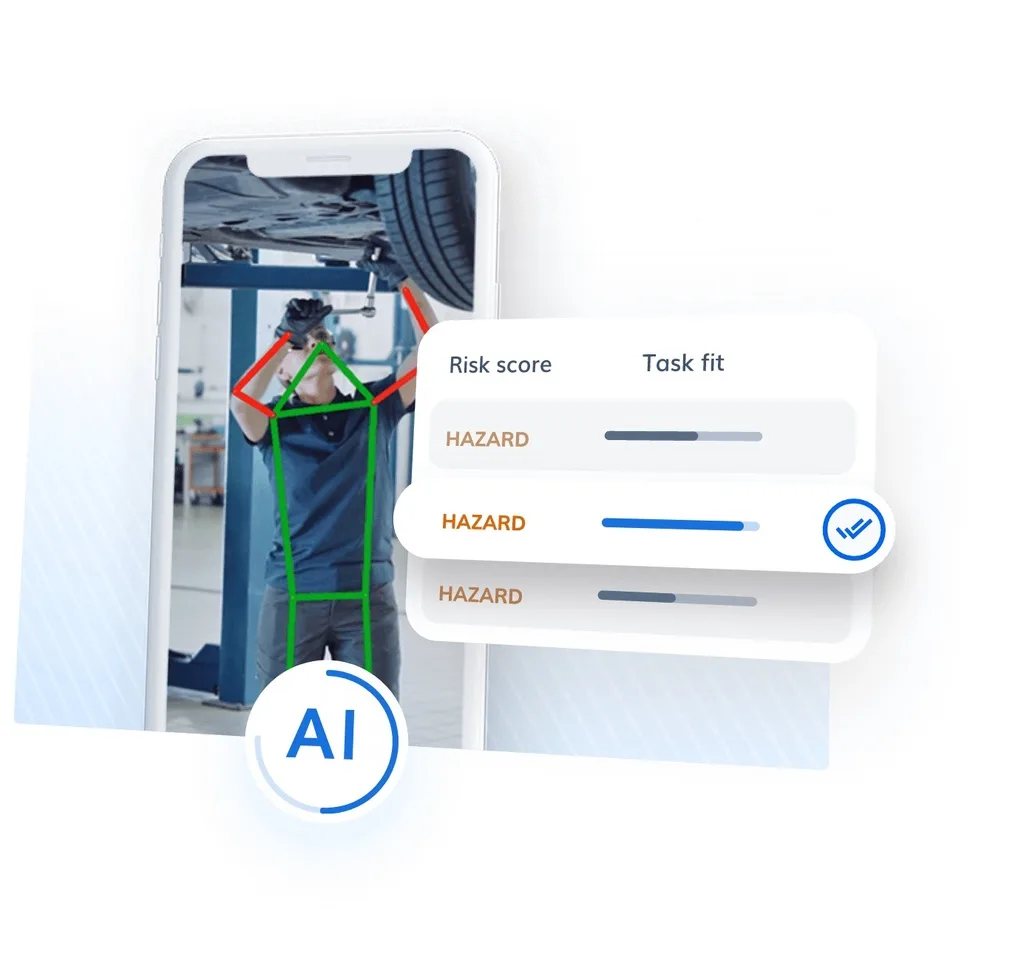

- WearHealth exoskeleton scanning: For anyone working in the manual handling sector, this type of technology is transformative, allowing the management team to focus training on areas where there are particular risks. The WearHealth AI technology can be used to match the right exoskeleton suit to the activity being performed, reducing the risk of injury. Video scanning technology is first used by a specialist safety consultant to assess a particular task. The worker is videoed performing a task, which is then processed by an algorithm to assess risk. An ergonomist reviews the data and produces a detailed report recommending the best exoskeleton suit to fit that task. Once a suit is selected from the recommendations, the organisation can trial its effectiveness using sensors on the neck, leg, and heart. The right exoskeleton for that task can then be fitted and used as required, based on the potential effectiveness and useability.

Stanley offers businesses a range of solutions that can help to reduce manual handling injuries, improve business efficiency, identify emerging risk and reduce costs by utilising the latest technologies in powered stair climbers and AI wearable ergonomic safety technology.

HSM publishes a weekly eNewsletter, delivering a carefully chosen selection of the latest stories straight to your inbox.

Subscribe here